Aluminum alloy is the material used to make high end cosmetic bottle caps. Cosmetic bottle caps are generally made of mirror polished aluminum. Polished aluminum caps typically require high brightness after oxidation, good coloring effects, smooth surfaces after stamping and low ear-making rates. Currently, the common polished aluminum caps on the market are made of 1070 mirror finished aluminum strip, which belongs to the 1000 series pure aluminum. It is mainly used as a material for manufacturing structural components with specific properties, and it has high plasticity, corrosion resistance, good electrical conductivity, and thermal conductivity.

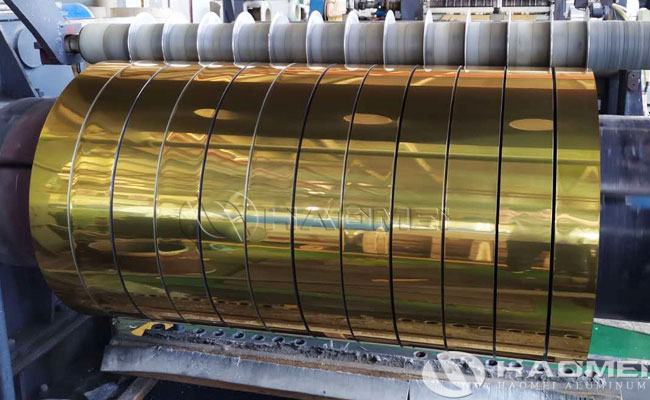

Mirror finished aluminum strip is used for indoor and outdoor wall decoration in the construction industry. The mirror finish aluminum sheet product requires strict flatness and surface quality, with high thickness accuracy. It also requires a glossiness of 700gu or above in the single longitudinal 60° mirror. The raw material used is aluminum strip with a thickness of 0.25-0.3mm, a surface roughness of 0.2-0.25μm, and even surface. The process of single-mirror rolling is achieved by controlling the following process parameters:

- the surface roughness ra of the upper working roll of the aluminum striprolling mill is 0.05-0.008μm, and the surface roughness ra of the lower working roll is 0.2-0.25μm;

- the rolling line height of the aluminum striprolling mill is controlled at 10-20mm to form a corner for the rolling aluminum strip within the roll gap;

- the diameter of the upper working roll of the aluminum striprolling mill is 5-10mm smaller than that of the lower working roll, and the rotational speed of the upper and lower working rolls is the same during rolling;

- the rolling speed in each pass is 80-150m/min, and the processing rate in each pass is controlled at 13-20%.

- Furthermore, the corners form a parabolic shape with the opening facing downwards.

- Furthermore, the angle of the corners is 5-10 degrees.

- Furthermore, the surface speed of the upper working roll is different from that of the lower working roll during rolling.

- Furthermore, the diameters of both the upper and lower working rolls of the aluminum striprolling mill are 240-260mm.

By adjusting the rolling line height of the aluminum strip rolling mill and the surface speeds of the upper and lower working rolls to control the stress state of the aluminum strip in the rolling deformation zone, the mirror rolling method of aluminum strip is optimized, and finally, a mirror finish aluminum strip with good flatness, high thickness accuracy, and a glossiness of 800gu or above in the single longitudinal 60° mirror is obtained.

Mirror finished aluminum strip materials are widely used in various fields, including lighting reflectors, indoor decoration, exterior decoration, household appliance panels, electronic product casings, furniture kitchens, and automotive interior and exterior decorations.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form